- 产品详情

- 产品参数

- 产品评论

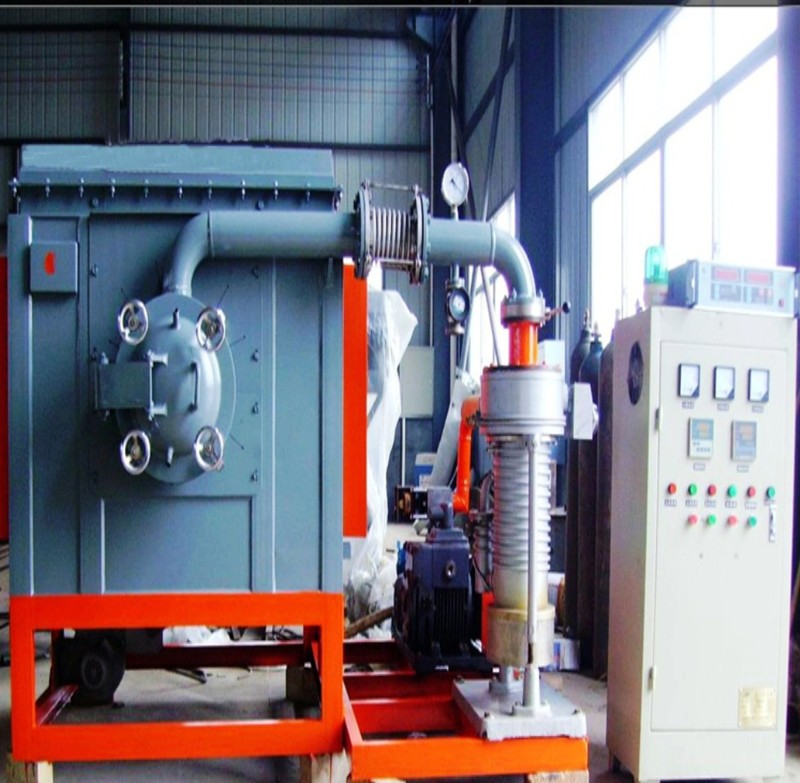

真空回火/退火炉

设备用途及原理

该设备主要用于高速钢、模具钢、不锈钢、合金钢、钛合金等合金材料的精密零件的真空光亮退火、回火、固熔时效、真空钎焊等。具有无氧化、无脱碳、表面质量好、变形小综合力学性能优异、无污染等特点。单室、内热式、布置紧凑的炉体结构。 配置对流加热装置,低温状态下炉温更加均匀。设计合理的隔热屏,保证炉膛内高的热效率。 此炉型采用电阻丝、电阻带进行外加热。

Application and Principles

This equipment is primarily applied to bright annealing, temper, solid fusion aging and vacuum brazing of high-speed steel, die steel, stainless steel, alloy steel, and titanium alloy and other precision components.

It is featured with no oxidation, no decarburization, good surficial quality, small transformation, extraordinary comprehensive mechanical properties, and pollution-free. Its structure is characterized with single room, inner heating type and compacted arrangement.

This furnace adopts electric resistance wire and belt to conduct external heating.

设备优势及特点

发热体可分成多区布置,各区独立控温,可编程PID调节。炉膛可整体移出,便于维护。 配备充气装置、可向炉内充入保护性气体或工作气体,充气流量可调。 配备内循环冷却装置,可加速炉内物料冷却,缩短工作周期,利于提高产品质量和工作效率。

Advantages and Features

Heating elements can be distributed among multiple districts, and each district can control temperature independently, and programmable PID regulation. Furnace hearth can be entirely removed out, convenient for maintenance.

It is equipped with gas filling device, filling furnace with shielding gas or working gas, and its flow can be regulated.

This furnace is equipped with internal-circulation cooling device, accelerating the speed of cooling down materials in furnace, shortening working period, and beneficial for improving product quality and performing efficiency.

设备主要技术参数Principle Technical Parameters

以下是设备产品技术参数,部分数据会随着产品创新改进,最新数据请联系我们:

Product technical parameters of equipment are presented as below, and partial of these data will be updated as the product innovation, please contact us if any latest data: 以上为标准配置,可根据客户要求进行调整。

以上为标准配置,可根据客户要求进行调整。

It is standard configuration above, and can be adjusted according to the demand from customers.