- 产品详情

- 产品参数

- 产品评论

射频等离子体球化制备粉末材料生产线

设备用途及原理

射频等离子体,具有能量密度高、加热强度大、等离子体弧的体积大,由于没有电极,不会因电极蒸发而污染产品。

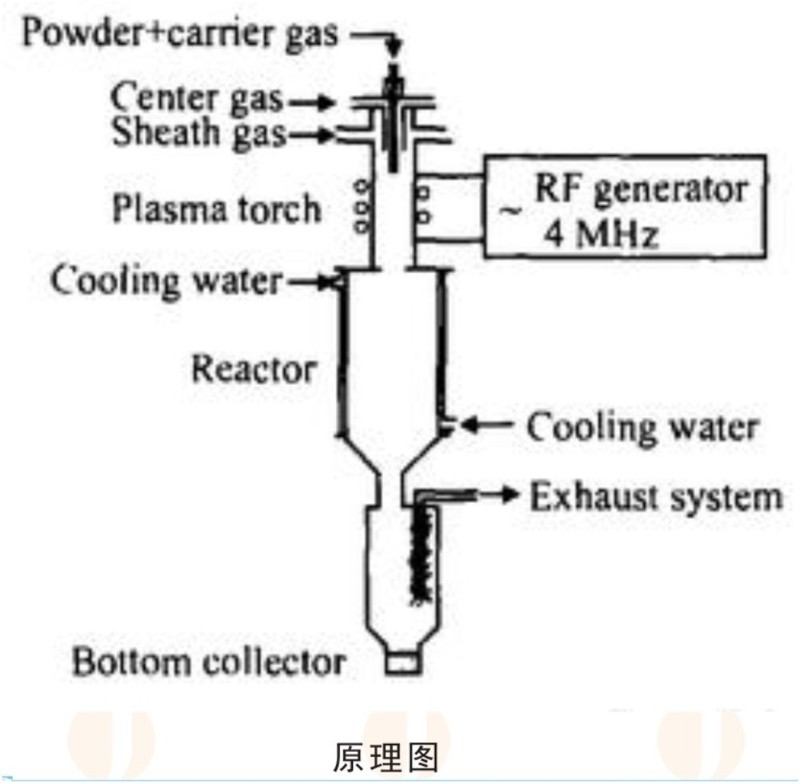

射频等离子体粉末球化技术原理,是在高频电源作用下,惰性气体(如氩气)被电离,形成稳定的高温惰性气体等离子体;形状不规则的原料粉末用运载气体(氮气)经送粉器喷入等离子炬中,粉末颗粒在高温等离子体中吸收大量的热,表面迅速熔化;并以极高的速度进入反应器,在惰性气氛下快速冷却,在表面张力的作用下,冷却凝固成球形粉末;再进入收料室中收集。

Application and Principles

Radiofrequency plasma possesses high energy density, strong heating strength, and its plasma arc is huge. Due to no electrodes available, it can not generate polluting products caused by electrode vaporing.

The principle of radio-frequency plasma powder balling technology refers to that inert gas (like argon) is ionized under the effect of high-frequency power supply and formed as hot inert-gas plasma; and the irregular raw powder is sprayed by vector gas (nitrogen) into the plasma through powder feeding device, and these powder particles absorb large amount of heat in hot plasma and their surfaces are melted rapidly; then these melted powder are sent into reaction device by extremely high speed, and chilled down under inert gas environment. Consequently, they are cooled down and solidified into spherical powder by surface tension; furthermore, they are sent into material gathering room and are gathered.

设备优势及特点

1、加热温度高、冷却速度快、无电极污染;

2、反应物料在等离子体中动态分散,可以避免粉体的团聚和长大,适合进行粉体的熔融球化;

3、可以制备钨、钼、Ti、W、WC、氧化铝、氧化硅、氧化锆等高温难熔金属及氧化物粉体;

4、粉末形状规则球化率高,表面光洁,流动性好;粉末致密性和堆积密度增大。

Superiorities and Features

1. Heating temperature is high, cooling speed is fast, and no electrode pollution is produced;

2. Reaction materials are dynamically dispersed in plasma, in this way it can avoid the accumulation and growth of powders, and it is applied to melting and balling of powder particles;

3. It is applied to preparation of hard-melted metal and oxide powders in high temperature, such as W, Mo, Ti, W, WC, Al2O3, silicon oxide, zirconia and so on;

4. The shape of powder is regular, its balling rate is high, the surface is bright and clean, and also has good flow-ability; The compactness and accumulation density of powder are increased.

设备主要技术指标

本设备保持行业高技术水平;详细技术资料请与我公司联系;

Major Technical Index

Relevant technical index maintains the most advanced level in this field; Please contact us if need detailed technology files.

设备核心模块结构技术

射频等离子体球化制粉设备由以下七部分及其周边部件组成:.

1、射频等离子体炬;

2、射频等离子体电源;

3、供气送粉系统;

4、反应室与收集室及支架;

5、真空抽气系统;

6、电气控制及测量系统;.

7、冷水机组。

Core Module Structure Technology

Radiofrequency plasma balling powder producing equipment is constructed with following seven components and peripheral components:

1. Radio-frequency plasma torch;

2. Radio-frequency plasma power supply;

3. Gas supplying and powder feeding system;

4. Reaction room and collection room, frame as well;

5. Vacuum pumping system;

6. Electric controlling and measuring system;

7. Cooling water machine unit.

射频等离子体炬:

整套设备的核心关键技术,具有自主知识产权的技术。采用陶瓷约束管,发散型喷嘴,可在惰性气体、还原、氧化气氛下工作。

Radio-frequency plasma:

It is the core key technology of the entire equipment, possessing proprietary intellectual property right. And it applies ceramic constraining pipe and divergent nozzles, allowing its performances under inert gas, reduction and oxidation environment.

高频等离子体电源:

功率100KW,频率3.0±0.5MHz.

High-frequency plasma power supply:

Power 100KW, frequency 3.0±0.5MHz.

供气送粉系统:

将物料输送至等离子体炬内,送粉粒径为10-200μm;供气系统采用精密的浮子流量计(4路),为炬提供工作气体(氩气)。反应室、收集室及支架:反应室与收集室采用双层水冷结构,其材质不锈钢,全部采用真空密封结构;支架采用碳钢喷塑,部分材料采用铝合金材料,坚固稳定安全。

Gas sending and powder feeding system:

It sends powder material into plasma torch. The diameters of sent powder particles are 10-200µm; on the other hand, gas supplying system applies precise float flowmeter (4 road), providing working gas (argon) for the torch. Reaction room, gathering room and frame: reaction room and gathering room utilize double-layer water cooling structure, and they are made of stainless steel, entirely adopting vacuum sealing pattern; the frame is spray-painted by carbon steel, partial materials are aluminum alloy which are strong, hard, steady and safe.

抽气系统:

配置为水环式真空泵+机械泵+罗茨泵+调节阀+管道+波纹管等,并进行切换,以维持系统启动与运行需要的负压。极限真空度8×10-2Pa。

Air pumping system:

It is equipped with water-circulating vacuum pump + mechanical pump + lobe pump + regulating valve + pipes + corrugated bellows, and switched to maintain required loading voltage for booting the system its operation. Extreme vacuum is 8 x 10-2Pa.

电气控制及测量系统:

温度、压力测量,过滤器反吹、送粉控制、气体流量调节等。

工业冷水机组:

30匹,采用风冷结构,为电源与等离子体炬冷却提供洁净冷却水。

Electric controlling and measuring system:

Temperature and pressure measurement, regulation on filter back flushing, powder sending control, and gas flow.

Industrial cooling water machine unit:

30P, adopting air cooling pattern and providing clean cooling water for power supply and plasma torch.