- 产品详情

- 产品参数

- 产品评论

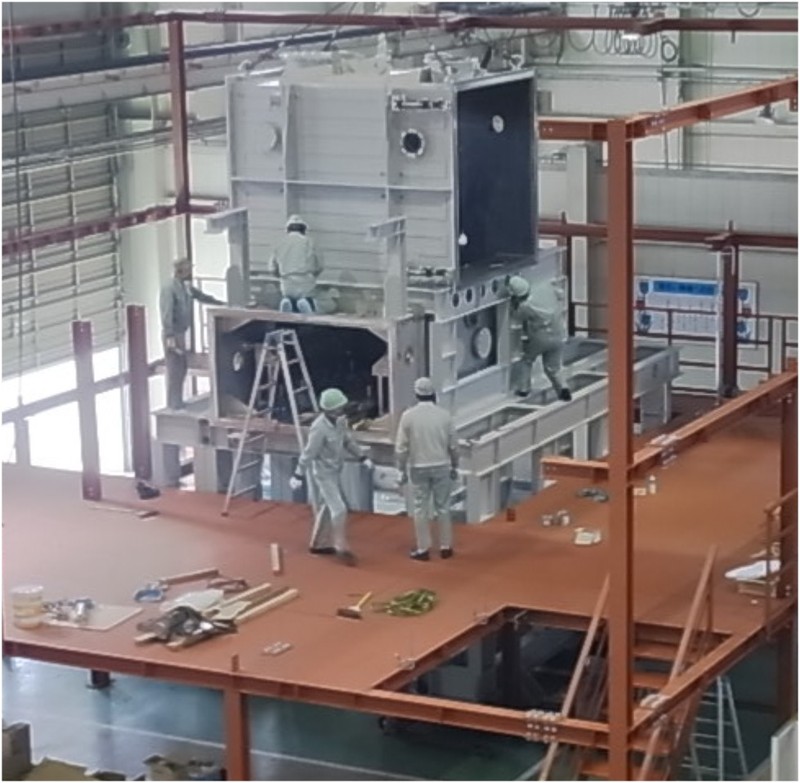

急冷法非晶粉末材料生产线(中日合作技术)

设备用途及原理

急冷法非晶粉末材料生产线是中日紧密合作技术,本设备系单辊式急冷装置。

其原理为在真空排气后,在Ar气体环境下熔融状态金属在设定条件下喷射到高速旋转中的冷却辊上,通过二次急速冷却方式制造非晶粉末材料。

目前主要供应设备适应于200Kg级,300Kg级,500Kg级粉末生产。

Application and Principles

Quench cool amorphous powdered material production line provided by is a close cooperation technology with Japan, and it is a single-roller quench cooling equipment.

Its working principle refers to that smelted metal is jetted onto quench cooling roller in high-speed rotation under given conditions in Ar gas environment, after vacuum exhausting, and then the amorphous thin band though quench cooling process.

Currently, the supplying equipment is mainly applied to powder production at 200Kg, 300Kg, and 500Kg grade.

设备性能及优势

提供的急冷法非晶粉末材料生产线是与日本进行技术合作的项目之一,为国内客户带来世界先进的技术设备,其中关键技术填补了国内技术空白,主要有以下优越性能:

1、真空到达压力:10-3Pa台(在为装填试料和喷嘴状态时);

2、泄露量:10-9PaM3/sec以下;

3、喷射压力:MAX0.1MPa;

4、熔炼量:5-500kg/按铁换算;

5、最高加热温度:1700℃;

6、常用加热温度:1500℃;

7、冷却辊转速:100-4000rpm;

Performances and Superiorities

Quench cool amorphous powdered material production line provided by is one projects technologically cooperated with Japan, bringing domestic clients with world advanced technological installation in which the core technology fills up the domestic technological gaps and possesses following advantageous performances:

1. Vacuum reaching pressure: 10-3 Pa (when filling with specimen and nozzle);

2. Leakage volume: less than 10-9Pam3/sec;

3. Injection pressure: MAX 0.1MPa;

4. Smelting capacity: 5-500g/based on iron;

5. Highest heating temperature: 1700℃;

6. Common heating temperature: 1500℃;

7. Cooling roller rotating speed: 100-4000rpm;

外部设备性能参数:

1、电源:三相220V 13KVA(客户须自备变压器)

2、冷却水:水量 25L/min,水压:0.35MPa(背压;0.1MPa以下)

3、惰性气体(Ar):置换容积 100L/次,压力0.5MPa。

Peripheral device performance parameters:

1. Power supply: 3 phases, 220V, 13KVA (clients need to prepare voltage transformer for their own)

2. Cooling water: 25L/min, water pressure: 0.35MPa (backpressure: less than 0.1MPa)

3. Inert gas (Ar): displaced capacity 100L/per time, pressure 0.5MPa.