- 产品详情

- 产品参数

- 产品评论

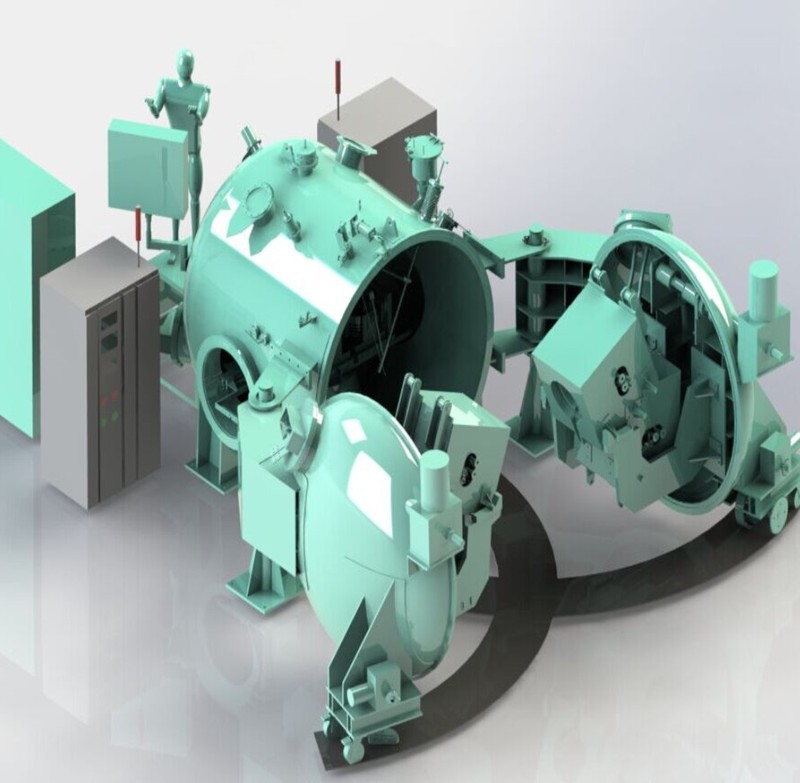

真空感应熔炼炉

设备用途及原理

真空感应熔炼炉是在真空条件下,利用中频感应加热原理,使金属熔化的真空冶炼成套设备。广泛用于科研和生产部门对镍基及其特殊钢、精密合金、钕铁硼、金属镝、活泼金属、高温合金、储氢材料、磁性材料、有色金属及其合金的研究与生产。

Application and Principles

Vacuum induction melting furnace is a uniformed vacuum metallurgic equipment for melting metals with the principle of medium-frequency induction heating under vacuum condition.

It is commonly utilized for studying and producing of nickel-based and its special steel, precise alloy, Nd-Fe-B, metal dysprosium, active metal, high-temp. alloy, hydrogen-storing material, magnetic material, colored metal and its alloy in research and production departments.

设备优势和特点

本设备应用先进的温度、真空检测等仪表及传感元件、数控式变频调整系统与可编程序控制器组成控制中心。具有以下显著优势:

1、具有超温、超压、欠压报警功能,并有防误操作联锁、互锁保护。保证设备安全、可靠运行;

2、真空泵采用低噪声节能型,抽气速率大,效率高;

3、线圈采用特殊工艺处理,寿命长不易变形;

4、采用高效电源,无功损耗小,效率高;

5、采用变频旋转式铸模装置,转速连续可调,可实现浇注多个模具的功能。

Advantages and Features

This equipment adopts advanced temperature and vacuum examine meters and inducing elements, digital-control variable frequency regulating system and programmable controller united control center. It possesses remarkable superiorities as below:

1. It is featured with alarming function of pressure exceeding, temperature exceeding, and pressure insufficiency, and also with anti-false operation chain-locking and interlock protection. Guarantee the security and reliable operation of the equipment;

2. Vacuum pump applies low-noise power saving type, and it is with high pumping speed and efficiency;

3. Coils is treated with special process, long lifetime and untransformed;

4. It utilizes high-effective power, low reactive loss, and high efficiency;

5. It utilizes variable-frequency rotary casting apparatus, and its rotating speeding is adjustable, achieving the function of casting multi-models.

设备核心模块结构

采用立(卧)式结构,由真空熔炼室、熔炼装置、旋转式铸模装置、真空系统、熔炼电源、自动控制系统、多工位观察窗、水冷系统、工作平台等组成。

Core Module Structure

It is applied with vertical (horizontal) structure, and consisted of vacuum melting room, melting device, rotary casting apparatus, vacuum system, melting power supply, auto-control system, multi-station observation window, water cooling system and working platform.