- 产品详情

- 产品参数

- 产品评论

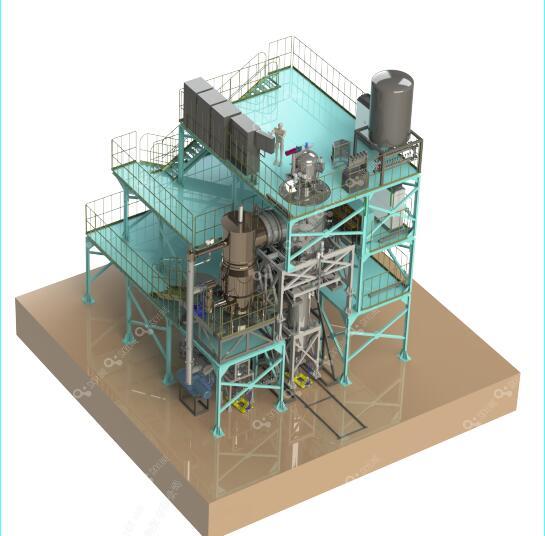

等离子体雾化制备粉末材料生产线

设备用途及原理

等离子体做为一种顶层工艺技术,在粉体材料的处理和合成制备方面的应用是行业领头的高新技术,目前已经成为许多国家的研究热点。

本设备系列通过把固体颗粒或丝材注入惰性气体等离子体中,使之在等离子体高温作用下完全蒸发,以蒸汽形式存在,然后利用气淬冷却技术进行快速冷却,使饱和蒸汽快速冷凝、成核、生长而形成超细粉末。

Application and Principles

The plasma, as a technology under ultimate conditions, is an advanced and new technology in the application for disposition and synthesis and preparation of powdered material, and currently prevails among studies in many countries.

Its working principles refer to several steps. First, inject solid particles into inert gas plasma and completely evaporate them under the high temperature of the plasma, existing as steam. And then cool them fast with gas quenching cooling technology, and finally allow saturated steam to be rapidly condensed, nucleated, grew and formed into superfine powder.

设备优势及特点

国内初创全系列先进超细/纳米粉体材料技术解决方案,自主研发销售,在钛、钛合金及难熔金属、3D打印粉末制备,以及军工航天级单晶基础原材料制备领域具有广阔应用市场。如:

1、金属:Cu,Fe,Al,Mo,W,Ni,Re,Ta,Ti 等及其合金;

2、氧化物:Al2O3, MgO,TiO2,ZrO2,SiO2等;

3、碳化物:WC,TiC,B4C,SiC等;

4、氮化物:AiN,TiN,BN,Si3N4等。

Advantages and Features

Owning to advanced technological superiorities, this equipment series are commonly applied to the preparation of superfine/nano-powdered material with highly chemical purity:

1. Metals: Cu, Fe, Al, Mo, W, Ni, Re, Ta, Ti and their alloys;

2. Oxides: Al2O3, MgO, TiO2, ZrO2, SiO2 and so on;

3. Carbides: WC, TiC, B4C, SiC and so on;

4. Nitrides: AiN, TiN, BN, Si3N4 and so on.

设备的创新点

1.组合模块式多功能输送原材料装置,包括:液体态、气态、粉末态原材料均匀精密送料装置、丝状原材料均匀精密送料装置、块状真空熔炼精密限流导流浇注装置;能满足不同状态的原材料生产;

2.等离子体电源和等离子体发生器也是本项目的关键技术创新点。为了提高雾化效率和雾化过程的稳定进行,本项目首次提出超高温等离子体发生器、等离子气体种类选择、以及气体流量和金属流率均合理匹配,可以生产高性能全系列金属单质和金属合金超细/纳米粉末,包括:化学活性强的金属 Mg/Al/Ti/Zr 及合金等;高温金属 W/Mo/Ni/Ta 及合金等;

3. 其专业设计的化学反应室能反应生成多种高化合度的超纯度多元素复合材料;

4. 提出了粉末粒度、氧含量与流动性精密智能控制的关键技术点;

5. 独创的急冷技术,制备纳米级粉末材料。

设备技术先进性

1.本设备具备增材制造用高性能粉末的装置,质效比高,智能控制集成度高;

2.首创粉末粒度在线测量及反馈精密控制技术,让行业技术从此脱离个人经验的依赖阶段,进入到智能制造时代;(选配)

3.粉末的氧含量过程综合控制技术;

4. 粉末的流动性指标关键控制技术;

本项目通过采用组合模块式均匀精密的原材料送料装置、专用雾化塔设计技术、雾化气体再循环,利用多向冷却粉末技术,加快雾化粉末冷却速度,减少雾化塔内单位体积粉末颗粒浓度,降低粉末碰撞几率,大大减低粉末之间的粘结。

5.提高-45+15μm区间粉末(应用于增材成型SLM等主流技术路径)收得率的关键控制技术;

本项目采用等离子气体雾化技术和合适的雾化工艺(主要是雾化温度和压力)制备粉末提高-45+15μm粉末的收得率和球形度,以保证粉末的良好的流动性。本项目研究得知,制备镍基、不锈钢粉末方面-45μm粉末的收得率大于70%,而且通过等离子体的结构优化和雾化工艺的配合可以减少-15μm粉末的含量,从而有效提高-45+15μ m 粉末的收得率;

6.化学活性材料表面钝化技术,保证产品使用过程安全性;

7.设备防静电设计技术。

技术参数

技术参数

1.技术参数

2.生产能力:30~60KG/小时(依据材料密度而不同)

3.功率:230KW

4.电源电压:380V,50Hz

5.极限真空度:10Pa

6.保护气氛:N2、Ar

7.冷却水额定压力:0.3MPa

8.气源额定压力:0.6MPa

9.雾化充气压力:≤0.5MPa

技术指标

1.粉末成品率分布:D70=15-45μm(以钛及钛合金粉末为例)

2.粉末氧增量:≤100ppm(以纯钛为例。实际生产过程中为应用安全,该类化学活性粉末材料必须表面钝化处理,氧含量应至800~1500ppm;)

3.粉末流动性:≤25s/50g

等离子感应熔炼定向气雾化制备粉末材料生产线

设备用途及原理

PIGA装置工作原理,是利用等离子流在水冷铜坩埚中进行熔炼,坩埚底部与一个感应加热导流喷嘴相连(导流喷嘴也是铜质材料),金属熔液经导流喷嘴进入真空雾化系统,利用惰性气体进行雾化制粉。

等离子感应熔炼定向气雾化设备适用于需要使用无陶瓷生产工艺的活性材料和难熔材料,如Ti、TiAl、FeGd、FeTb、Zr和Cr等.

Application and Principles

The performance principles of PIGA equipment refer to the smelting in water- cooling copper crucible with plasma jet. The bottom of the crucible connects with an induction heating fluid-direction nozzle (the fluid-directing nozzle is made of copper), through which metal liquid flow out into vacuum atomization system and is generated into powder with inert gas.

Plasma induction smelting directional gas atomization equipment is applied to the active material and hard-smelted material requiring for free-ceramic production technology, such as Ti, TiAl, FeGd, FeTb, Zr, and Cr and so on.

设备优势及特点

本设备主要有以下特点:

1、适合制备活性材料粉末(比如钛)或难熔合金;

2、无陶瓷生产工艺,可制备高纯度、超细纳米粉末材料。

设备核心模块结构技术

等离子感应熔炼定向气雾化设备由以下九大核心模块及其周边部件组成:.

1、等离子熔炼炉;

2、雾化系统;

3、雾化罐体;

4、粉尘收集系统;

5、真空系统;

6、冷却系统;

7、气体系统;

8、电气及控制系统;

9、中频感应电源。

等离子体旋转电极离心雾化制备粉末材料生产线

设备用途及原理

等离子体旋转电极离心雾化技术原理,是以金属或合金制成自耗电极,其端面受离子体炬加热而熔融为液态,通过电极高速旋转的离心力将液体抛出并粉碎为细小液滴,继之冷凝为粉末。保护气氛可选用惰性气体,最好是氦气。因为氦气的热导率最高,约为氩气的10倍,既能提高冷却速度,又可改善离子体炬特性。

等离子旋转电极离心雾化制粉设备能制取高纯度球形高温金属粉末材料,其制取的粉末材料粒度为50-500微米,是制造高推重比航空发动机涡轮盘、压气机盘等高温转动部件的原材料。

Application and Principles

The principle of plasma rotation electrode centrifuge atomization technology refers to that the end face of self-consuming electrode made of metal or alloy is melted into liquid state with being heated by plasma torch, then the liquid is thrown out of by centrifugal force caused by electrode high speed rotating and smashed into tiny droplets, and consequently these droplets are congealed to be powder. Inert gas can be an available option to be protecting gas, and among which helium is the best due to its highest thermal conductivity, about 10 times of argon, not only increasing cooling speed but also improving the properties of the plasma torch.

Plasma rotation electrode centrifuge atomization preparation powder equipment can produce spherically hot metal powdered material with high purity and its particle size is 50-500 nanometers. These powdered material can work as the raw material for producing high thrust-weight-ratio turbine disc and compressor disc of aero-engine, and other hot rotating components.

设备优势及特点

本设备具有以下技术优势和特点:

1、可以制备镍基高温合金、钛合金等难熔金属和活泼金属粉末,也可制备钽、钨、钴、铬等各种合金粉末。

2、金属熔融和雾化金属过程中完全避免和与耐火材料接触,消除了非金属夹杂物污染源,可生产高洁净度的粉末材料.

3、粉末形状规则,球形率高,表面光洁,流动性好;

4、无卫星球粉末及空心粉末;

5、粉末粒度分布范围较窄。

6、由于凝快克服了偏析现象,可以制取许多特殊合金粉末。

Advantages and Features

This equipment possesses following advantages and features:

1. It can prepare hard-melted metal and active metal powder such as nickel-based hot metal alloy and titanium alloy, as well as various alloy powder such as Ta, W, Co, Cr and other metal-based alloy.

2. It is required to completely avoid fire-resistance materials during the course of metal melting and atomizing, eliminating pollution sources mixed with non-metal medias and thus it can produce high-cleanliness powdered material.

3. The shapes of these produced powder are regular, among which the spherical powder is produced at high possibility, its surface is bright and clean and has good mobility;

4. No satellite-ball powder and hollow powder are produced by this equipment;

5. The scope of particle size distribution is relatively narrow.

6. It can produce several special alloy powder because of segregation phenomena is conquered by curds.

设备核心模块结构技术

等离子体旋转电极离心雾化设备由以下七大核心模块及其周边部件组成:.

1、雾化室及集粉系统;

2、等离子枪装置;

3、传动装置组件(高转速动密封,电机,轴承,电极给进装置);

4、真空系统;

5、冷却系统;

6、气体系统(气氛控制,等离子枪循环);

7、电气及控制系统。

Core Module Structure Technology

Plasma rotation electrode centrifuge atomization equipment is consisted of seven major core modules and peripheral components as below:

1. Atomization room and powder collection system;

2. Plasma gun appliance;

3. Transmission appliance unit (high rotation speed sealing, electrical machine, bears, and electrode movement device);

4. Vacuum system;

5. Cooling system;

6. Gas system (gas environment control, plasma torch circulation);

7. Electric and control system.

直流等离子体直接雾化制备粉末材料生产线

设备用途及原理

一种等离子雾化制备高纯度球形超细/纳米粉末材料的技术原理,包括棒材、丝材,粉末颗粒原材料,或液体、气体原料通过专用的送料装置直接送入对称高温等离子体炬形成的等离子焦点区,温度可以高达5000K以上,原材料在高温下被瞬间液化或汽化或热反应分解/合成,并被等离子体高速冲击分散雾化成超细液滴或气雾状,在雾化塔中飞行沉积过程中,与连续通入雾化塔中的冷却气体进行快速热交换,激冷凝固成各种材质的高化学纯度球形超细或纳米级粉末材料。

Application and Principles

It is a technological principle applied in plasma atomizing preparation for high-purity spherical superfine / nanometer powdered material, including rod material and wire material. Powdered particle raw material or liquid and gas raw material are directly sent by particular material feeding device into the plasma focused area formed by symmetrical hot plasma torch, and the temperature can reach 5000K above. Under such high temperature, raw material will be immediately liquefied or vaporized or decomposed/synthesized with thermal reaction, and also be high-speed impacted, dispersed, and atomized into superfine liquid droplets or gas smoke by symmetrical plasma.

And then, during the course of flying and sedimentation in atomizing tower, they are allowed to have rapidly heat exchanged with cooling gas continuously fed in atomizing tower, and consequently chilled and solidified into various spherical superfine or nanometer powdered material in high chemical purity.

设备优势及特点

本设备以生产纳米级先进粉末材料为主要特点,在航空航天等高科技新材料领域有着不同的优势:

1、可生产各种超细/纳米级金属粉末,如镍、钴、钛、锆,钽等球形粉末。

2、如果通入一些能够产生合成反应的混合气体,可以生产某些氧化物、碳化物及氮化物等高化学纯度的陶瓷粉末。

3、用等离子直接雾化制取的粉末粒度一般为纳米(nm)级,含氧量很低,具有很高的活性。因此烧结性能很好,烧结产品的各项力学性能大幅度提高。另外用此方法生产的超细金属粉末或氧化物粉末还具有极优良的磁电和防腐蚀性能,电磁波吸收特性等,在电子半导体材料、航空航天等高科技新材料领域很有前景。

Superiorities and Features

This equipment is primarily featured with producing nanometer advanced powdered material, and possesses unique superiorities of producing high-technological new material applied in aerospace field:

1. It can produce various superfine/nanometer metallic powder, such as Ni, Co, Ti, Zr, Ta and other spherical powder.

2. If fed in some mixed gases which can generate synthetic reaction, it can produce some oxides, carbides, and nitrides and some other high chemically purified ceramic powder.

3. The particle size of the powder directly atomized by plasma is usually nanometer (nm) grade, and has low oxygen content and high activity. Thus, these powders have good sintering character, and each mechanical property of the sintered products have been greatly improved. In addition, the superfine metallic powder or oxide powder produced in this way also possesses amazing magneto-electric character and anti-corrosion property, as well as electromagnetic wave absorption specialty. This equipment has a bright future of producing high-technological new material applied in aerospace field and electronics and semiconductor materials.

设备核心模块结构技术

等离子体旋转电极离心雾化设备由以下五大核心模块及其周边部件组成:.

1.送料系统,

2.对称等离子体炬及电源;

3.真空系统;

4.雾化塔和反应室;

5.粉末收集装置以及后续与之相连的气体粉末分离系统、粉末收集系统、气体净化再循环利用系统。

Core Module Structure Technology

Plasma rotating electrode centrifugal atomization equipment is consisted of five major core modules and peripheral components as below:

1. Material feeding system;

2. Symmetrical plasma torch and power supply;

3. Vacuum system;

4. Atomization tower and reaction room;

5. Powder collection device and it connects with gas-powder separating system, powder gathering system, and gas-purification recycling and utilizing system.